MAINTENANCE OF MOBIL PRODUCING NIGERIA UNLIMITED (AFFILIATE OF EXXONMOBIL) INDUSTRIAL HYGIENE EQUIPMENT. (Ongoing)

This service includes but not limited to:

- Ensuring ALL MOBIL PRODUCING NIGERIA Industrial Hygiene equipment provided are duly calibrated.

- Interface with appropriate OEM or any reputable maintenance provider to ensure equipment maintenance and calibration is completed as and when due, and does not exceed a period of 3months.

- Provision of any other equipment maintenance services as deemed fit.

- Procurement/replacement of equipment as necessary.

- client: Mobile Producing Nigeria Unlimited (Affiliate of ExxonMobil)

- Location: Nigeria

- Surface Area: Ongoing

VISUAL SURVEY OF ASBESTOS CONTAINING MATERIAL (ACM) CONTAINMENT STATUS ON TRIDENT XIV RIG – Shelf Drilling. (Completed)

This service included but not limited to:

- Review of previous ACM containment report and status of implementation of recommendations.

- Review Shelf Drilling Policy and Trident XIV O & M and status of their implementation.

- Inspection of the facility to ascertain that all previously identified ACM are secured, intact and non-friable.

- Identify new or overlooked exposed ACM on the facility during the inspection.

- Make recommendations on how the identified issues can be addressed.

- client: Shelf Drilling

- Location: Nigeria

- Surface Area: Completed

MAINTENANCE OF CHEVRON NIGERIA LIMITED INDUSTRIAL HYGIENE EQUIPMENT. (Ongoing)

This service includes but not limited to:

- Ensuring ALL CHEVRON NIG LTD. Industrial Hygiene equipment provided are duly calibrated.

- Interface with appropriate OEM or any reputable maintenance provider to ensure equipment maintenance and calibration is completed as and when due, and does not exceed a period of 3months.

- Provision of any other equipment maintenance services as deemed fit.

- Procurement/replacement of equipment as necessary.

- client: Chevron Nigeria Limited

- Location: Nigeria

- Surface Area: Ongoing

COLLECTION AND ANALYSIS OF CHEMICAL SAMPLES FOR NLNG. (Ongoing)

This service includes but not limited to the following:

- Ensuring relevant samples including biological samples are timely collected and analyzed by an accredited industrial hygiene laboratory.

- Maintain a contract with a reputable and accredited industrial hygiene laboratory for the analysis of relevant samples e.g., Benzene

- Analysis for BETX and any other volatile organic compounds as well as metals, organic/inorganic acids, asbestos, silica, dust, etc.

- client: Nigeria Liquified Natural Gas

- Location: Nigeria

- Surface Area: Ongoing

MAINTENANCE OF NLNG INDUSTRIAL HYGIENE EQUIPMENT. (Ongoing)

This service includes but not limited to:

- Ensuring ALL NLNG Industrial Hygiene equipment provided are duly calibrated.

- Interface with appropriate OEM or any reputable maintenance provider to ensure equipment maintenance and calibration is completed as and when due, and does not exceed a period of 3months.

- Provision of any other equipment maintenance services as deemed fit.

- Procurement/replacement of equipment as necessary

- client: Nigeria Liquified Natural Gas

- Location: Nigeria

- Surface Area: Ongoing

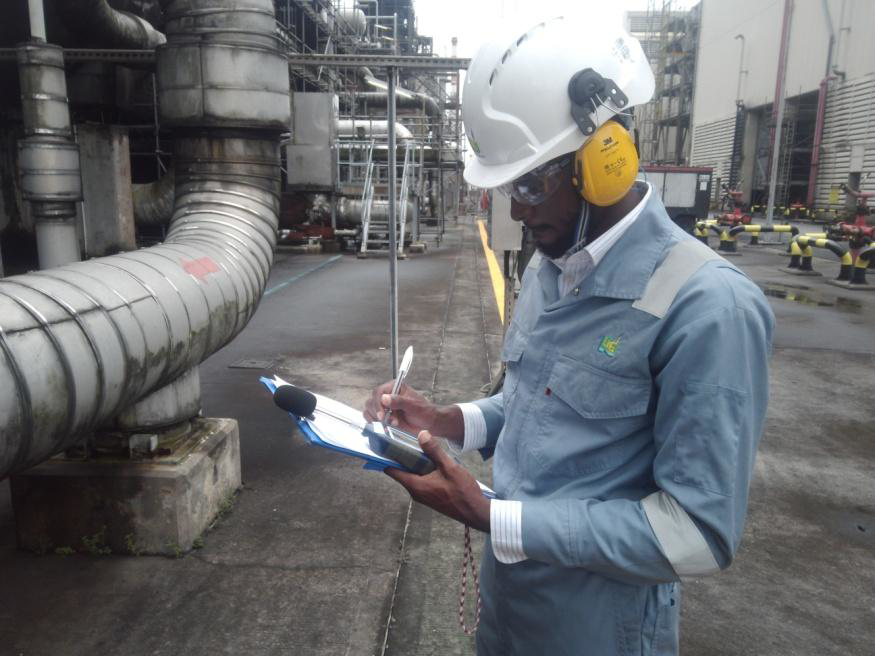

PROVIDING INDURSTRIAL HYGIENE SERVICES TO NIGERIAL LIQUIFIED NATURAL GAS (NLNG) LTD. (Ongoing)

GRADI Health and Safety Ltd use qualified professionals to provide this service, which include but not limited to the following:

- Conduct workplace assessments including Health Risk Assessment (HRA), and develop and/or recommend corrective actions to eliminate hazards or reduce the hazards to as low as reasonably practicable (ALARP).

- Conduct workplace exposure monitoring for exposure to chemical hazards, physical hazards, biological hazards, ergonomic hazards, as well as psychosocial hazards

- Provide advice to management on methods, procedures and devices to control health hazards associated with current or proposed processes and operations

- Provide occupational health/hygiene inputs for HSE policy reviews and HSE Cases and HSEMS

- Participate in Catering & Hygiene inspections as well as participate and assist in implementing, HSE-MS, ISO 14001, OHSAS audit recommendations

- Provide SME support for HSE activities, include but not limited to HAZID, HAZOP, HFE studies, Ergonomic training, etc.

- Ensure proper documentation of all Industrial Hygiene activities/workplace monitoring.

- Provide any other industrial hygiene service as deemed necessary by the contract holder, so as to ensure the health and safety of employees, contractors and visitors

- client: Nigeria Liquified Natural Gas (NLNG)

- Location: Nigeria

- Surface Area: Ongoing

MENTORING WORK ACTIVITY OF NEW INDUSTRIAL HYGIENE (IH) PERSONNEL IN MEGI – Mobil Equatorial Guinea Inc. (Completed)

- Work with new Industrial Hygiene personnel in Occupational Health Medicine Dept. to have a good understanding of the basic principles of Industrial Hygiene through classroom training and discussions

- Work with the personnel to gain knowledge on the process of workplace Health hazard risk assessment

- Train new IH personnel on the basics of the Health Hazards of the workplace in MEGI

- Give the personnel hands-on training on how to carry out health hazard surveys and monitoring including process of report writing and reporting.

- Train personnel on several administrative processes for Industrial Hygiene including filling systems (hard copy and electronic files), filing of individual survey and monitoring documents.

- Understanding links to and how to relate with other Units that work closely with IH.

- Preparing for and understanding the process of Integrity management and Controls management audits

- Understanding the Administrative role of the Industrial Hygiene personnel in the Occupational Health Integrity Management system.

- Give personnel training on the Public Health activity of the Industrial Hygienist, including complete Health inspections of on shore and off shore facilities e.g., rigs and offshore platforms etc.

- Personnel has gone on to acquire the BOHS Certification in Industrial Hygiene Competence within 3 years of this mentoring activity.

- client: Mobil Equatorial Guinea Inc.

- Location: Equatorial Guinea

- Surface Area: Completed

TOTAL UPSTREAM COMPANIES IN NIGERIA – AKPO FPSO NOISE MAPS PRODUCTION AND VIBRATION STUDY. (Completed)

1. AKPO FPSO NOISE MAPS PRODUCTION

- Undertook a complete review of the current noise Maps on AKPO FPSO

- Noise measurement carried out in the various locations (Modules) of FPSO

- Advice on areas requiring mandatory double hearing protection must be specified (Noise levels of 95dB A or above).

- Produce laminated paper based Noise Maps of the various modules with appropriate colour coding for the measured noise level

2. A HAND AND ARM /WHOLE BODY VIBRATION (HAV/WBV) SURVEY IN THE AKPO FIELD

- Undertake a survey in the AKPO Field (AKPO FPSO), to identify all the jobs, equipment and tasks that predispose personnel to any form of HAV/WBV.

- client: Total Upstream Companies in Nigeria

- Location: Nigeria

- Surface Area: Completed

AOS ORWELL WORKSHOP NOISE AND WELDING FUME SURVEY (Completed)

1. AOS ORWEL WORKSHOP NOISE SURVEY

- Noise measurement of all areas of the workshop

- Produce the noise maps for the workshop

- Personal noise monitoring of work groups in the workshop

- Analysis of the result to identify the personnel exposed to noise above the exposure limit

- Make recommendations on how best to protect impacted personnel

2. AOS ORWEL WORKSHOP WELDING FUME SURVEY

- Take sample of welding fume generated during welding activity in the workshop.

- Using a United Kingdom accredited Service (UKAS) laboratory determine the air concentration of all the applicable hazardous metals and other components of the welding fume sample.

- Identify workers who are exposed above the exposure limits to any of the components.

- Make professional recommendations on how best to reduce exposure where applicable.

- client: AOS Orwell

- Location: Nigeria

- Surface Area: Completed